Vertical Bolted Concrete Cement Silo

Volume:30T~1000T

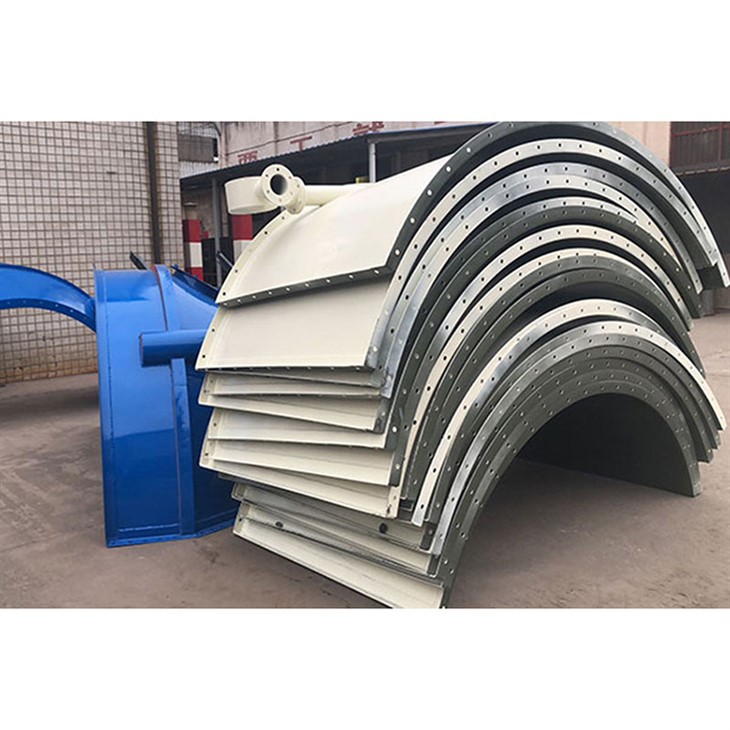

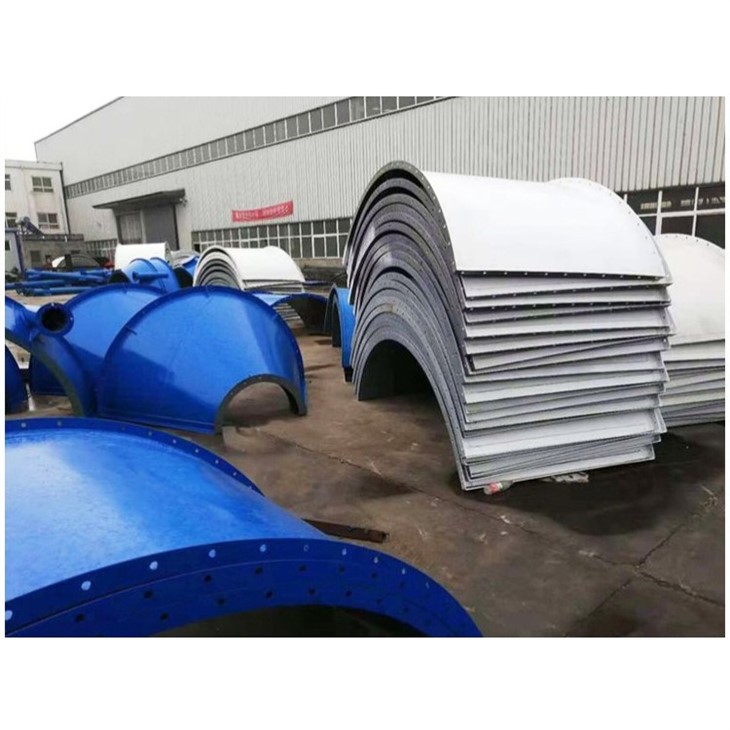

Vertical cement tanks are also called vertical cement silos. Vertical cement silos are a closed storage silo for storing various bulk materials such as grain, cement, fly ash, etc. The flake vertical cement silos or assembled cement silos are large in size and difficult to transport, so they need to be disassembled and assembled. Therefore, most vertical cement tanks are installed at the customer's production site.

Product Details

Our product

Structure: The vertical bolted concrete cement silo consists of four main parts: cover, wall section, cone and support legs. All parts are pressed by special machines and molds, especially the wall part, which can be replaced at every position on the wall.

The cement silo is equipped with a full set of accessories, equipped with facilities such as automatic dust collector, butterfly valve, automatic arch breaking and upper and lower material level indicators.

Details

Dust Collector

A dust removal device (electric or pulse) is installed on the top of the cement storage silo, which can effectively absorb suspended particles in the silo and reduce pollution to the surrounding environment.

Butterfly Valve

1) The sensor uses a high-precision sensor, which is accurate in weighing and quick in response;

2) The pneumatic butterfly valve is tightly sealed, reliable in action, simple in structure, small in size, light in weight, and cost-effective.

Liquid Level Meter

The bolted powder cement silo level device can sense the storage height of the material in the silo.

Arch Breaking Device

The lower cone of the vertical cement silo is equipped with an air-blowing arch breaking device, which uses a small electromagnetic reversing valve in the air control box to control the release of compressed air to break the arch of cement and various powdery materials to avoid powder accumulation and blockage.

Vibrator

50kg/100kg or bagged cement powder can be transported to the mixer through the cement hopper and screw conveyor. There are blades in the cement hopper, which can damage the bag, causing the material to fall to the bottom and be sent to the mixer by the screw conveyor.

Product Features

1) Easy to transport, assemble and disassemble.

2) Short construction period and low cost. On-site construction and quick installation. The cement silo is made of thin steel plates, which greatly reduces the weight, thereby reducing costs and freight.

3) Good airtightness and wide range of applications. We use special equipment for rolling silos for bending and biting to ensure the process quality of any cement silo parts. So. The sheet-assembled cement silo is well sealed to prevent moisture and penetration.

4) Environmental protection and cost saving. Our mobile cement silo is equipped with a dust collector on the top, which can achieve good environmental protection effects. Our dust collector can collect and reuse materials, which are usually generated during the production process.

Certifications

Our Company

Packaging And Shipping

Application

Bolt cement silos are widely used in concrete mixing plants, dry mortar plants, mines, water conservancy projects, tunnels, bridges, highways, bulk material transfer at docks, etc.

FAQ

Q: When the powder in the cement silo is blocked, an arch-breaking device is needed. How to use it correctly?

1) Regularly check whether the pipeline and connection of the arch-breaking device are loose or leaking;

2) Regularly check whether the starting element of the arch-breaking device in the cement silo (cement tank) is flexible and works normally;

3) Regularly check whether the structure of the arch-breaking device in the cement tank is damaged, and frequently check whether the welding parts of the hanging and supporting devices of the arch-breaking device are firm and whether the bolts are loose. The piston of the arch-breaking device should be removed and cleaned frequently;

4) Ensure that the arch-breaking device is clean and not too dusty;

5) Regularly check the circuit of the arch-breaking device and solve any problems in time.

Hot Tags: vertical bolted concrete cement silo, China vertical bolted concrete cement silo manufacturers, suppliers, factory, concrete weigh batcher, concrete mixer machine drum, mobile mixing plant, js1000 concrete mixer, concrete batching machine, js2000 concrete mixer

The vertical bolted concrete cement silo is designed and produced in a modular manner. It is also convenient to transport and install.

|

Volume |

Diameter |

Silo Body Height |

Layers of Silo Body |

Pieces Each Layer |

Weight |

|

30t |

3000 mm |

2200mm |

1.5 |

4 |

3T |

|

50t |

3000 mm |

4260 mm |

3 |

4 |

4.5 T |

|

100t |

3000 mm |

8700 mm |

7 |

4 |

6 T |

|

150t |

3160 mm |

13000 mm |

9 |

4 |

9 T |

|

200t |

4000 mm |

11360 mm |

8 |

5 |

12 T |

|

200t |

4500 mm |

8700 mm |

6 |

6 |

12 T |

|

300t |

5300 mm |

8700 mm |

6 |

8 |

17 T |

|

500t |

6800 mm |

7300 mm |

8 |

8 |

21 T |

|

600t |

6800 mm |

8700 mm |

6 |

8 |

28 T |

|

800t |

8000 mm |

10100 mm |

7 |

10 |

43 T |

|

1000t |

8000 mm |

13200 mm |

9 |

10 |

56 T |

Previous

Bolted Type Cement SiloYou Might Also Like

Send Inquiry